How To Change Fork Oil On 2005 Hyosung Gt250?

Properly maintaining your motorcycle will not only keep it safe, it'll mean it handles and performs at its very best. While almost of us wouldn't hesitate to change the engine oil in our bikes every year, few of the states consider the fact that the front fork legs also have oil in, which is being constantly worked as you ride.

The rear stupor (or two) on your bike likewise incorporate oil, but these can't be serviced without specialist tools – y'all can discover out how some can exist serviced by Grand-Tech interruption for just £150 by clicking here .

As well keeping the oil in your forks fresh, at some indicate the seals will fail. Hither'southward how you can gear up them for yourself…

The oil in your forks gets worked incredibly hard, so why wouldn't y'all regularly replace it with a quality lubricant?

How do I look subsequently my motorcycle forks?

Once of the main reasons fork seals become damaged is through pitting and rust on the fork stanchion (or tube / slider) – as the tubes move up and down in the legs, the seals keep the oil in. But any imperfections to the chrome can tear the seal, allowing the oil to leak out. Forks with aureate or black nitride coatings, for example, don't suffer the pitting of chrome forks; whatever harm needs to be checked by a specialist.

Small-scale imperfections in the chrome tin exist carefully removed with very fine emery paper and some WD-twoscore, but if the damage is too bad they'll accept to exist re-chromed or replaced. If re-chroming, it's important to use a specialist fork repair company, who'll understand how critical the tolerances are.

Basically, like the balance of your bike, keep the forks clean. Don't be tempted to utilise seal cleaning tools that slide under the seal while information technology'due south in place – these can push grit into the fork body, which volition notice its way into the damping shims and valve, and often cause more damage to the seals. If the grit seal that sits on tiptop of the fork leg is letting dirt get by, it – and the oil seal – need replacing.

Pitting to the forks stanchions will speedily tear the seals

How long should my fork oil, the seals and bushes final?

How long your fork seals and bushes last will depend on how and where y'all ride – if you're riding in very dusty areas, over a lot of pot-holes (or landing a lot of ham-fisted wheelies) you might discover them failing in a few years. Mine were both leaking, but the bike's 21 years old; it's simply done xviii,000 miles but it'south been sabbatum doing nothing for almost a decade – those seals will beginning to perish over time.

Oh, and it used to exist owned by the ex-editor of Fast Bikes magazine, though he promises me he didn't ride this similar he did printing bikes. It was his mum's bike earlier that – maybe she was a bit of a hooligan.

The oil will only terminal a limited time, and the Haynes manual shows that it should be replaced every two years / 16,000 miles on this 1999 Kawasaki ZX-6R.

The very best way to keep your forks at their best is to service them. While every 2 years would be ideal, assuming they have no problems, every three to iv years (unless yous're on rails or riding an awful lot) should be fine. You tin service them yourself, just information technology's worth knowing that Yard-Tech suspension – for example – will practise a full strip and rebuild, with new seals, for effectually £150. This includes completely disassembling and cleaning the shim-stack that controls the damping, which tin can only be done with specialist tools.

Oil on the stanchions is a sure sign of a blown fork seal

How practice I know when my fork seals and bushes demand replacing?

The bushes will wear over time, leaving some pocket-sized amount of play between the leg and the stanchion. Realistically though, you'll come across the fork seals fail first, and if y'all're replacing those, y'all might every bit well replace the bushes also, specially equally they have to come out to get the seal out.

The seals are more than obvious when they neglect – you lot'll encounter traces of oil on the fork stanchions almost the grit seal; if at that place is any, wipe it make clean then bounce the forks a few times to bank check it wasn't simply road filth.

What parts do I need?

Ever supercede your seals and bushes as a pair – if one leg is showing problems, the other won't exist far behind. A pair of fork grit seals (the seals you can encounter) for this 1999 ZX-6R are £20.62 from Kawasaki, while a pair of the oil seals that sit underneath them are £22.08. And no, yous tin can't merely replace the dust seal (which is easy to remove without taking the forks autonomously).

Yous should also ideally replace the snap ring on each leg that holds the oil seals in place – ii of those toll £5.18 from Kawasaki, while the 2 inner and two outer bushes add effectually a farther £45. That's a total of over £92 for OE.

Fortunately, Wemoto offers complete rebuild kits – for this bike you lot'd get all the seals, snap rings and bushes for merely £41.29.

If a fork stanchion is damaged and you need to replace information technology a new i from Kawasaki will ready you back £244.51. S bent fork leg can sometimes exist straightened, but if information technology's creased it must be replaced. Wemoto sells Italian-made Paolo Tarozzi fork stanchions for £140.28.

You'll also need oil – cheque your Haynes or possessor'southward manual for the correct weight, just information technology's typically 10W. Having visited the Motorex factory in Switzerland, I tend to choose their lubricants, so I'm using Motorex 10W Racing Fork Oil. On this bike, later on the forks accept been stripped, it requires upwards to 592cc per leg, and so two 1-litre bottles were needed at £fourteen each.

What tools do I need?

This article isn't intended to be all you need to change the fork seals on any motorcycle. I'm basing it on my 1999 Kawasaki ZX-6R, merely your bike will accept its own unique needs, so I thoroughly recommend buying a Haynes workshop transmission first. My promise is that this will requite you the confidence to take on the job for yourself, only merely with a workshop guide specific to your car volition y'all take the correct procedure. Think that Bennetts customers tin can save a massive 40% on Haynes manuals at Bennetts Rewards . You lot'll also demand the post-obit…

- Allen keys

- Spanners

- Socket gear up

- Apartment-bladed screwdriver

- A tool to drive the new oil seals and superlative bushes in, or a length of pipe that just fits over the outside of the fork stanchion

- Fork oil level tool, or a vernier caliper, or a ruler

- Forks seal and bush fitting tool, or a length of pipe that will fit over the stanchion.

- An impact wrench. You might be able to manage without one, but you'll need an assistant.

- Brake cleaner

A suitably sized slice of tube can be used as an alternative to a seal / bush fitting tool

How do I alter the fork seals on my motorbike?

You actually do need a clean space to work on your forks; any dirt that gets into them as they're rebuilt volition impair their damping operation. If yous're looking to fully service the forks, I would recommend you send them to a company like K-Tech , equally they'll clinically rebuild them, which includes stripping the shim stacks and cleaning them (you demand a lathe to turn the locking nut off). Just £150 for the service includes new seals, though you will have to pay for the bushes if they demand replacing (they won't be much extra).

If you lot're simply replacing the seals and bushes, yous'll be able to go most of the intermission make clean, but don't attempt to remove the shims.

Only piece of work on ane fork leg at a time, to avoid mixing parts betwixt the ii, which will accept worn slightly differently.

Step ane: Air current off the bound preload and spiral down the rebound adjuster

If you lot want to set the preload dorsum where it was, count how many turns yous make earlier winding it all the way off. Also air current the rebound adjusting screw all the way in – it'll make setting the top of the top cap easier afterward.

Always avoid using an adjustable spanner if you tin can - this was all I had to fit the fork caps when I loosened them earlier taking them to Nick's workshop

Step ii: Loosen the top caps

Before removing the forks from the bicycle, loosen the bolts on the top yoke that hold them in identify, and the handlebar clip-ons (if fitted). At this phase, don't loosen the bottom yoke bolts. With the forks held in place simply by the lesser yoke, you can loosen the fork acme caps – they only demand cracking open, just you lot must not grip the stanchions in a vice (they could be easily distorted) so now is the last chance you'll take to do it.

Step 3: Remove the forks

Before dropping the fork legs out, take notation of where they sit down relative to the superlative border of the height yoke.

You'll already have taken the wheel out, but you'll too need to remove the mudguard, calipers and anything else that's fixed to the forks. Make sure you lot hang the calipers somewhere on the bike, so the brake lines aren't put under strain.

Pace 4: Remove the lesser bolt

The exact method of dissembling forks is going to vary depending on the age of the bike, and whether they're upside-downwards or right-way-up; having a Haynes manual is essential.

Never clamp the fork stanchion in the vice, and so to concord the fork, protect the jaws of the vice and hold onto both of the caliper hangers and as much of the metallic that makes them up as possible. Still accept care through.

On this ZX-6R, the left fork leg has the axle nut in – remove this to become at the bolt inside the bottom of the fork leg, which holds the damper cartridge in place.

Past far the easiest way to remove this bolt from a correct-way-upwards fork is using an impact wrench, which will rattle it out. If you tin't become concur of one, y'all should be able to undo the bolt by asking an banana to shrink the stanchion into the fork leg equally difficult every bit they can – the pressure from the bound should finish the cartridge from rotating. Of course, at that place is a Kawasaki tool available to concord the cartridge.

Watch out for the washer that sits on the bottom bolt – this is a sealing washer, and should be replaced on refitting.

If your bicycle has upside-down forks, the disassembly method could exist significantly dissimilar – check your Haynes manual.

Pace five: Drain the old oil

Haynes suggests a different social club to stripping the forks down, and if you're unsure, information technology'southward best to follow that. Nonetheless, Nick drains the old oil out of the bottom bolt hole, pumping the stanchion in and out. Go out information technology to sit for every bit long every bit you can to drain as much equally possible.

Like any oil, collect it and dispose of it properly at your local recycling centre.

Stride six: Remove the dust seal

Using a apartment-bladed screwdriver, advisedly prize the dust seal off the top of the fork leg.

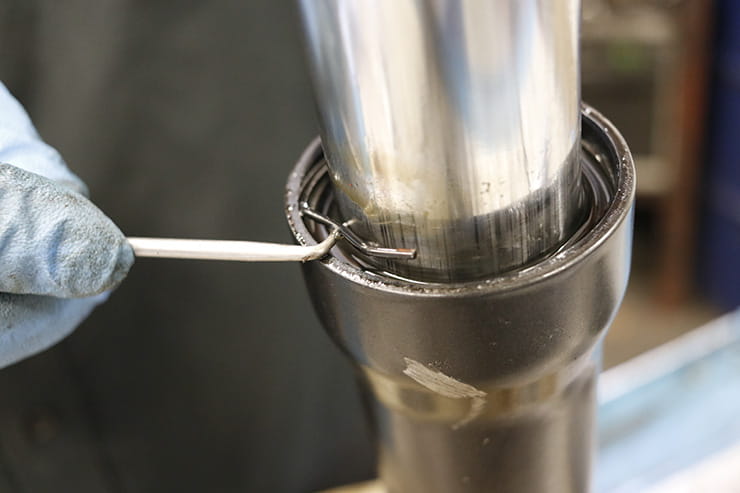

Step 7: Remove the snap ring

With a smaller screwdriver or a option, remove the snap band that sits on meridian of the oil seal.

Step 8: Pull the fork stanchion out

Again, the guild will vary co-ordinate to the bike, merely at this stage Nick has left the fork tiptop attached to the stanchion because he'south fully-removed the lesser bolt that holds the cartridge in, otherwise, the fork peak will need to be removed from the damper rod.

To remove the seal on these forks, hold the fork leg steady and pull the stanchion upward and outwards sharply until the bushes inside hit each-other and start to drive out. You lot'll need to do this a few times until the seal and bush pop clear and the stanchion is removed. If you've taken the cartridge out with the stanchion, check the bottom of the fork leg, where the seat of the cartridge will probably still exist sitting.

Step 9: Remove the bushes and seals

Keeping an eye on how everything fits for later, the bottom bush needs to be prized open up with a apartment-bladed screwdriver in social club to pop it off the bottom of the stanchion, then the top bush, followed past its washer and the oil seal can be slid off.

Step 10: Remove the cartridge from the stanchion

A total service from a company similar K-Tech would see the cartridge itself disassembled and thoroughly cleaned, merely that requires a lathe and some specialist cognition.

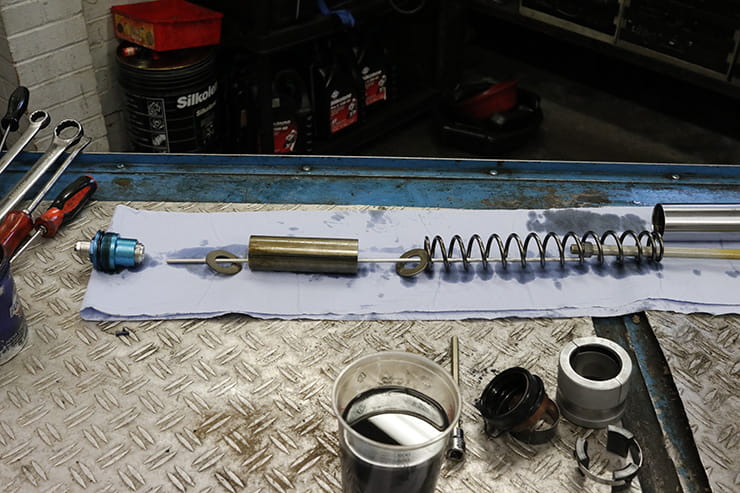

Assuming you lot remembered to loosen the elevation cap while the fork leg was nonetheless in the cycle, unscrew it fully and slide the stanchion down. You can then agree the preload adjuster while loosening off the lock-nut. Then remove the cap, which will enable you to remove the damping adjuster rod and the damping cartridge, complete with the washer, spacer, some other washer and the jump (notation how the smaller, tighter coils are at the bottom on this bike). Watch out for the seat that goes betwixt the bottom of the cartridge and the base of the fork leg – it'll likely still be in the leg.

Lay all the parts out on a clean bench, ideally on a newspaper workshop towel.

Step xi: Fix any minor pitting

On chrome fork stanchions, run your fingernail along whatever marks or pits to feel for any small ridges; using 1200 grit emery newspaper and some WD-40, these can be carefully sanded away. Take it very gently though – cease regularly to look for the shiny expanse that yous're sanding; you just want to take the small lip off, not abrade the residue of the chrome too much.

Remember, if the forks need re-chroming, go to a specialist that tin can proceed the thickness exactly inside tolerance, or the diameter of the stanchion might non friction match the seals. Severely damaged stanchions should be replaced.

If, once the edges take been taken off, y'all're left with a hole in the chrome acquired by corrosion, you really should replace the stanchion or accept it properly re-chromed. If you were actually skint, you could endeavour filling the damage with chemical metal, and so sanding it downward, but it's not recommended.

Good tip: Watch for pitting on the whole stanchion

"While it's pitting on the swept area of the fork stanchions that will crusade damage to the seals in use, you demand to remove whatever rust and pitting from the surface area above information technology likewise," says Nick Nomikos, owner and MoT tester at The Two Cycle Centre in Harpenden . "Any imperfections there will tear at the new seals when yous slide them on."

Footstep 12: Clean everything

Using a solvent cleaner like brake cleaner, thoroughly clean all the parts of the suspension, using a paper towel or rag with something to poke it downwardly to clean right within the leg, making certain you don't leave anything in at that place. If you take a compressor, blow the parts dry.

Make clean the seal and prune seats in the top of the fork leg with an abrasive cloth.

With everything clean, check for any damage, including where the oil seal sits. If y'all don't have a run-out guess, you can check the fork stanchion is straight past rolling it on something flat, like a canvass of glass. Also cheque the spring for any signs of impairment, and that it's not sagged – the length information technology should be is in the Haynes manual; in this case it shouldn't be shorter than 264mm.

Y'all tin can inspect the bushes for signs of wearable, but as the forks are apart it's worth changing them, especially equally they're less than £20 from Wemoto, or part of the rebuild kit we're fitting hither.

You should besides check that the damper rod moves freely up and downward within the cartridge – if it doesn't, information technology'll need replacing.

Pace xv: Fit the new bottom bush

The new bottom bush-league volition need gently opening with a apartment-bladed screwdriver earlier it can be popped onto the bottom of the stanchion. Then wipe some of the new fork oil on the bush and pour a little into the fork leg to lubricate the sides.

Step 14: Refit the cartridge

Slide the cartridge all the way into the stanchion, making sure the seat is on the lesser – this has to continue the correct way effectually then that it mates with the bottom of the cartridge. You tin at present refit the bottom bolt and sealing washer. This should be torqued upward using the Kawasaki tool to hold the cartridge, just nigh people will nip it up with an impact wrench on a low setting. Yous can fully tighten it when the fork is reassembled with the spring back in to utilise pressure and an assistant compressing information technology if you don't have an touch on wrench.

Step xv: Fit the top bush-league

Push the stanchion down into the fork leg as far as information technology'll go, and then wipe some fork oil on the new top bush-league and slide it down over the stanchion until it sits squarely above the recess in the summit of the fork leg.

You'll need a plumbing fixtures tool to tap information technology fully home, or a suitable piece of piping that will fit over the stanchion. At a push, you could use a apartment-bladed driver to tap it home, moving around 90° with a gentle tap each time until it's fully seated, just make sure you accept the washer sat over the elevation of the bush before doing and so.

Expert tip: Drive the bush-league and seal separately

"Some people drive the height bush-league, washer and oil seal all down together," says Nick Nomikos, owner and MoT tester at The Two Wheel Centre in Harpenden . "But the extra force going through the oil seal worries me; doing information technology properly doesn't take much more time."

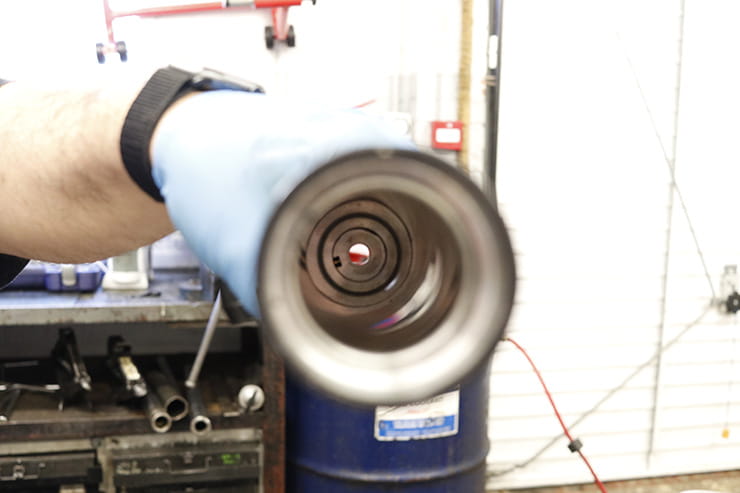

Stride sixteen: Fit the new oil seal

After double-checking the washer is in identify above the bush, wipe some fork oil on the lip of the new oil seal, and then cheque which manner up information technology is; the markings should be on the peak face. Slide the new seal over the stanchion and down into the summit of the fork leg. Using the section of pipe again, or a seal-driving tool, button the seal home until it'south properly seated and the groove is conspicuously visible for the retaining snap clip to become into.

Step 17: Fit the retaining clip and new dust seal

Popular the snap clip into the groove above the oil seal (use the new one that came with the Wemoto kit if you bought that), so bank check it'due south properly seated by rotating it. You can at present run a lilliputian fork oil around the inside of the new dust seal and slide it into place. This should push button down by hand, just you can carefully push button the edges down using the side of a screwdriver'south shaft if needs be.

Stride 18: Prime the cartridge

There is a special tool available to pump the damper rod, but you lot should be able to accomplish the rod to practise it past hand. Fully shrink the stanchion and the damper rod, then slowly pour in the specified corporeality of oil – it'll be at the forepart of the 'Frame, suspension and concluding drive' chapter in your Haynes manual; on this cycle 500cc will be more than plenty for at present.

Reach in and take the damper rod to pump it fully up and down ten times. Then pump the stanchion upward and down ten times.

Step nineteen: Fix the air gap

The quantity of oil you put in isn't as important every bit the altitude it is from the top of the stanchion. After making certain all of the air is out and that the cartridge is full of oil, button the damper rod and the stanchion right down, and so mensurate the distance from the meridian of the stanchion to the oil. Y'all can do this with a ruler or a vernier caliper, but the easiest way is with a fork oil level tool, which is basically a graduated tube with an adjustable plate and a syringe. I fabricated one one time with a narrow pipage taped to a ruler and an old syringe.

Add or remove oil until the air gap is as specified (in the same identify in the Haynes transmission). Hither information technology's 103-107mm.

Step 21: Check the peak cap lock nut

The lock nut on the top of the damper rod sets the height of the cap every bit it screws downwardly. If you'd wound the rebound adjuster all the mode down before removing the top cap, y'all'll be able to apply that to find the correct position, and but screw the lock nut back upward to see the cap. Even so, if you didn't, don't screw it all the way in at present, instead, set the position of the locknut before putting the spring back on – on this model, at that place should exist 11mm of thread above the nut.

Stride 20: Fit the bound

Pull the damper rod upwardly and so driblet the spring down over the rod with the tighter-wound coils to the bottom (this is on my 1999 bike, on the previous model of ZX-6R, they become to the top, so bank check in your Haynes manual). Next drop the washer, then the spacer, then the other washer on. Finally, drib the damping adjuster rod back into the damper rod.

Stride 21: Screw on the meridian cap

If yous had wound the rebound adjuster all the fashion in earlier removing the cap, now just air current the cap back onto the meridian of the damper rod until the adjuster screw just touches the adjuster rod. Do NOT tighten it whatever further; all you need to exercise now is wind the lock nut back up to meet and secure against the bottom of the preload adjuster in the top cap. You'll need to counter-hold the pinnacle of the preload adjuster, non the top cap itself.

The official way is to set the lock nut 11mm down, as described in stride 21, then set the bottom of the rebound damping adjuster to exist 25mm from the bottom edge of the preload adjuster – you will demand a Vernier caliper to measure out this. Using this method, screw the top cap down until it meets the locknut at 11mm, and then tighten the lock nut against the bottom of the preload adjuster, holding the top of the adjuster with a spanner.

Step 22: Screw the stanchion to the fork cap

Pull the stanchion up and screw it onto the fork cap, making certain it'south not cross-threaded. Tighten it as all-time you lot can by hand.

If yous hadn't fully tightened the bottom bolt (which holds the damper cartridge), have someone compress the fork while you nip it up.

Step 23: Finish tightening the fork caps in the bike

Pass the fork back through the top and bottom yoke, carefully setting the height of it relative to the top edge of the top yoke. Of course, make certain both fork legs sit at exactly the same height on either side.

Simply tighten the bottom yoke bolts (to 20Nm on this bike), then tighten the fork top caps to the correct setting (23Nm hither). Now yous tin can tighten the top yoke bolts and refit the prune-on bars, before fixing everything else dorsum on.

If yous can't exercise this job yourself, your dealer volition be happy to take the work on. While prices will vary, Nick Nomikos, owner and MoT tester at The Ii Wheel Centre in Harpenden (too equally our technical advisor) says he'd charge between but £xc and £120 plus parts for loose forks. This is a not bad price, though it also shows the good value of a full service from Thou-Tech .

How To Change Fork Oil On 2005 Hyosung Gt250?,

Source: https://www.bennetts.co.uk/bikesocial/news-and-views/advice/bike-maintenance/replace-fork-seals-oil-bushes-diy-motorcycle-maintenance

Posted by: knappspass1986.blogspot.com

0 Response to "How To Change Fork Oil On 2005 Hyosung Gt250?"

Post a Comment